Implement factories with the lowest production cost and the highest quality

With over 20 years of experience, our engineers have developed a unique level of expertise with an integrated platform of solutions and building programs for the industry.

It all started with basic feasibility studies and soon developed into groundbreaking end-to-end efficiency and plant optimization tools known as Qoncept Engineering program.

More recently, the Business Analytics unit developed bespoke tools to integrate broader business metrics into engineering investment and optimization, and the latest development has been the introduction of Artificial Intelligence benefits into the process, providing unique insights and self-learning capabilities into the business and engineering mix.

- Production and Logistic process analysis

- Process data

- Definition of production capacity

- Storage, transfer and dosing of raw materials

- Personnel for plant production

- Area classification

- Preliminary cost estimates

Model Simulation

- System architecture

- Process control function

- Production flexibility objectives

- Marketing and process order background studies

- Storage, transfer and dosing materials

- Overview model simulation

Turnkey Projects

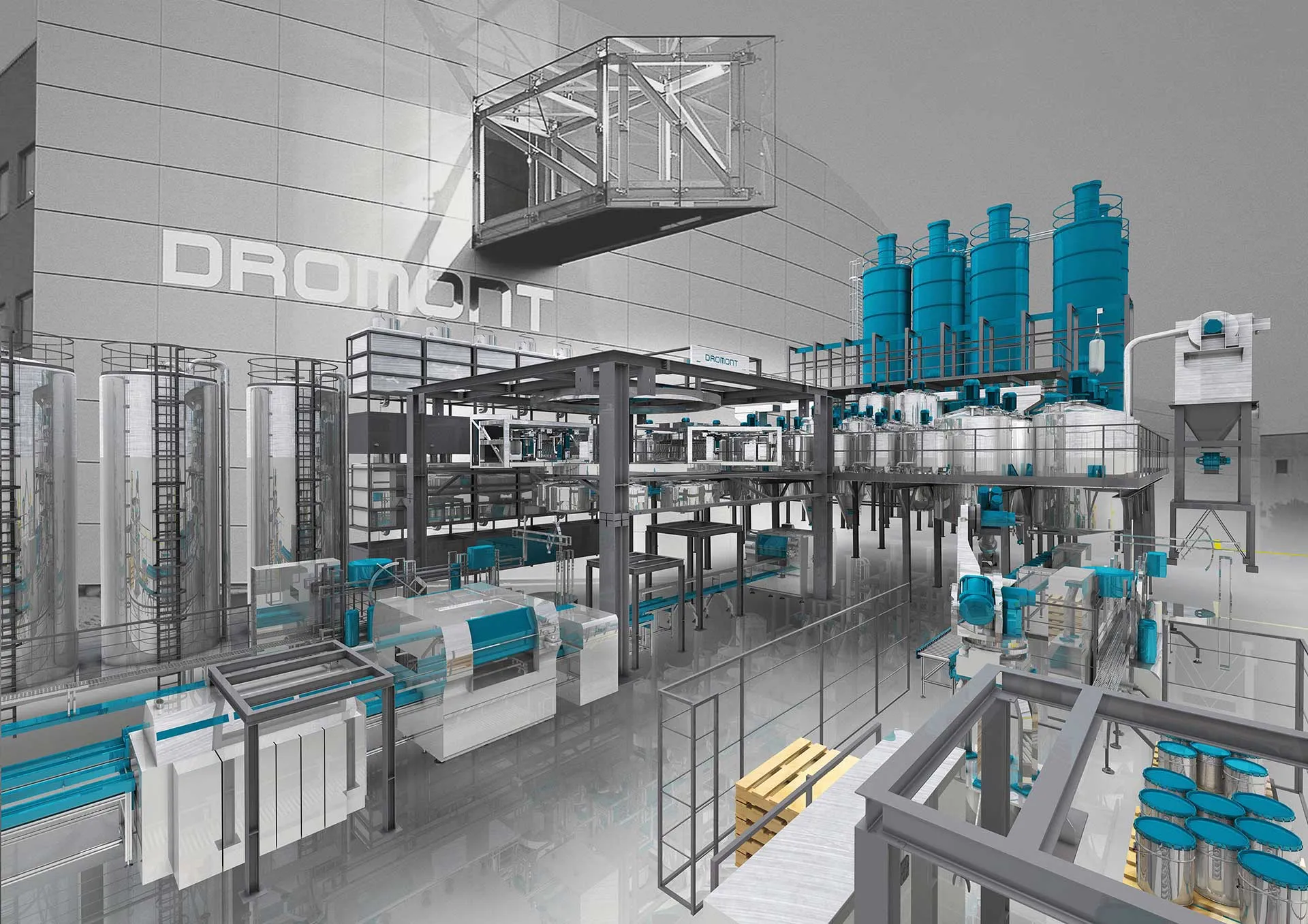

We leverage our combined DromontGroup experience and innovations to implement factories with the lowest production cost and the highest quality by utilizing our industry leading technology. We provide process designs from Feasibility Analysis and KPI definition up to Project and Site Management, from Design and Manufacture up to Installation and Start-up of the Plant.

Project management

Detail engineering

Process flow scheme and layout

Reception of raw materials

Storage, transfer and dosing

Dispersion and mixing

Grinding, cleaning and filling

Equipment construction and erection

Tests and pre-commissioning

Commissioning, training and start-up

MISURA FACTORY M.E.S.

Manufacturing Execution System

Web Based

Cross Platform

Complete Process Data Collection

Calculation of OEE (Overall Equipment Effectiveness)

TEEP (Total Effective Equipment Performance)

Data Analysis and KPI

Access to data on-the-go

Unlimited Licenses

Software & Automation

Automation to boost productivity and capture extra-profit from Factory Operations

Dromont’s In-House Software Department consists of internal programming engineers working on updating our software platform to the latest innovations as well as integrating our machines into the customer’s Enterprise Resource Planning (ERP) system.

This department can customize the interface software to the customer’s exact needs, testing the software prior to installation, and programming the software to communicate with the customer’s system.

By using the very stable base platform of the Dromont software, Dromont’s engineers can then create many different options that will allow the customer to manage the entire plant.