To thrive in Industry 5.0, DromontGroup has invested in a 5-years R&D program with the goal of being part of this revolution, follow the latest advancements in smart and sustainable production

PERFECTA

Our Business Units

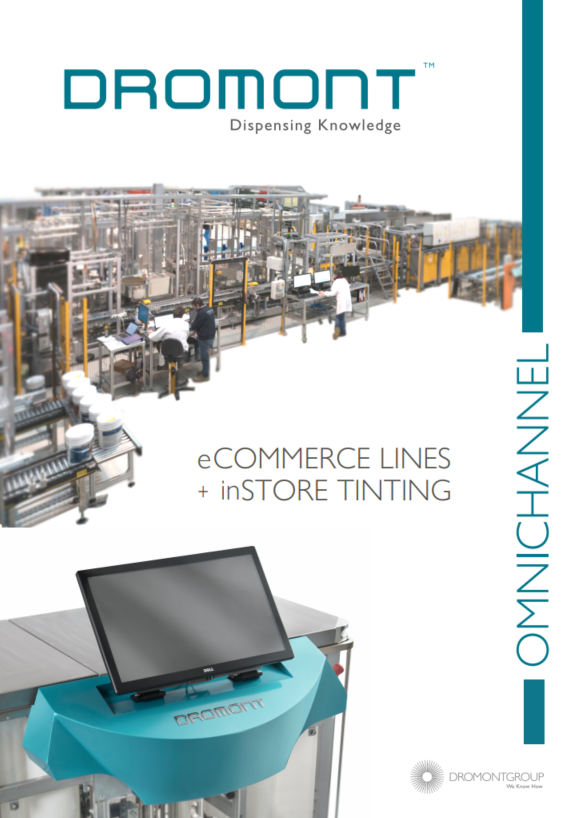

Dromont Omnichannel Engineering provides online retailers with filling and tinting strategies to receive orders in any size through e-Commerce platforms. Our retail tinting machines are also used for custom tinting at paint stores and outlets.

Accuracy and Speed are the cornerstones where Dromont established a new standard.

PAINT ONLINE

All paint SKUs ready in few seconds without inventory for your e-Commerce orders.

LABOUR FREE

Full Robotic Platform: order processing, manufacturing, pick, pack, and dispatch

IMMEDIATE PROCESSING

Any sheen, color and packaging processed in real time.

ZERO INVENTORY

Dromont technology platform offers mass personalization of on-line paint orders, eliminating working capital, warehouse handling burdens with zero inventory.

Solutions For Your Industry

Our Business Sectors

Latest News

Our Business Updates

To thrive in Industry 5.0, DromontGroup has invested in a 5-years R&D program with the goal of being part of this revolution, follow the latest advancements in smart and sustainable production

Come to find us and book your slot via giulia.melioli@dromontgroup.com

Contact Our Team

Dromont S.p.A.

Via Borzone, 42

12060, Grinzane Cavour (CN), Italy

P.IVA/VAT 02023900042

M sales@dromontgroup.com

T +39 0173 230430

M serviceinplant@dromontgroup.com

T +39 0173 230467

M serviceretail@dromontgroup.com

T +39 0173 230466