Real-time remote monitoring capability

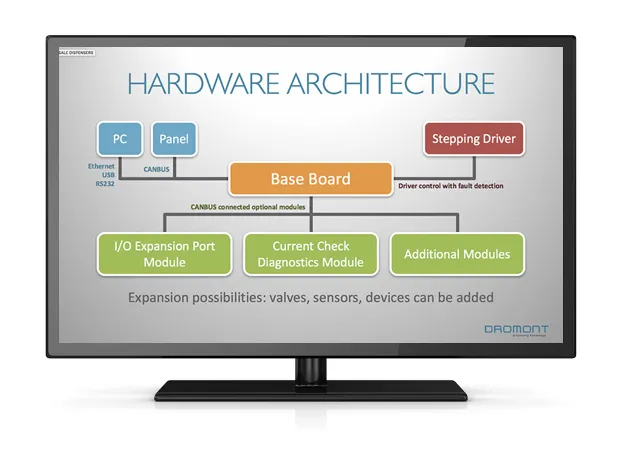

Dromont in-House Software Department consists of internal programming engineers working on updating our software platform to the latest innovations as well as integrating our machines into the customer’s Enterprise Resource Planning (ERP) system. This department can customize the software interface to the customer’s exact needs, testing the software prior to installation, and programming the software to communicate with the customer’s systems.

By using the very stable base platform of the Dromont software, Dromont’s engineers are able to then create many different options that will allow the customer to manage the entire plant.

Main advantages

- Faster devices

- Multitasking operations: autocap, shelf and pumping groups should move simultaneously

- Noise level reduction

- Smarter diagnostic: more precise error messages

- Increased connectivity: status check from anywhere

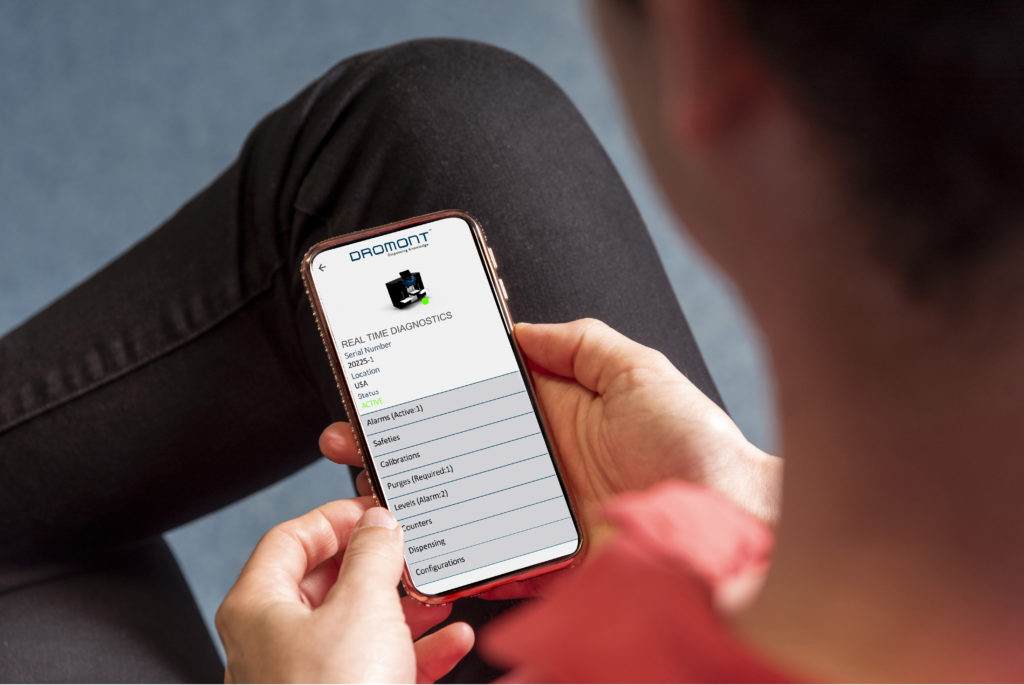

Thanks to the new DromontApp it is also possible to remotely monitor in real time machine status and performances. It allows operators, service technicians and service companies to collect data and show messages for a predictive maintenance support; guiding customers to quickly identify the origin of a downtime and immediately return to operation.

Data collected are mainly calibration data, counters, canisters colorants level, alarms history, configuration settings, dispensing and purges.