Complete formula dispensing into portable tanks or drums

High productivity systems for dispensing bases/converters and colorants directly into 200 lt drums, 500 lt, 1000 lt tanks. The solution includes mixing of finished goods and allows for the removal of FG stock, thus delivering the orders straight away after production to the final customers.

Selecta

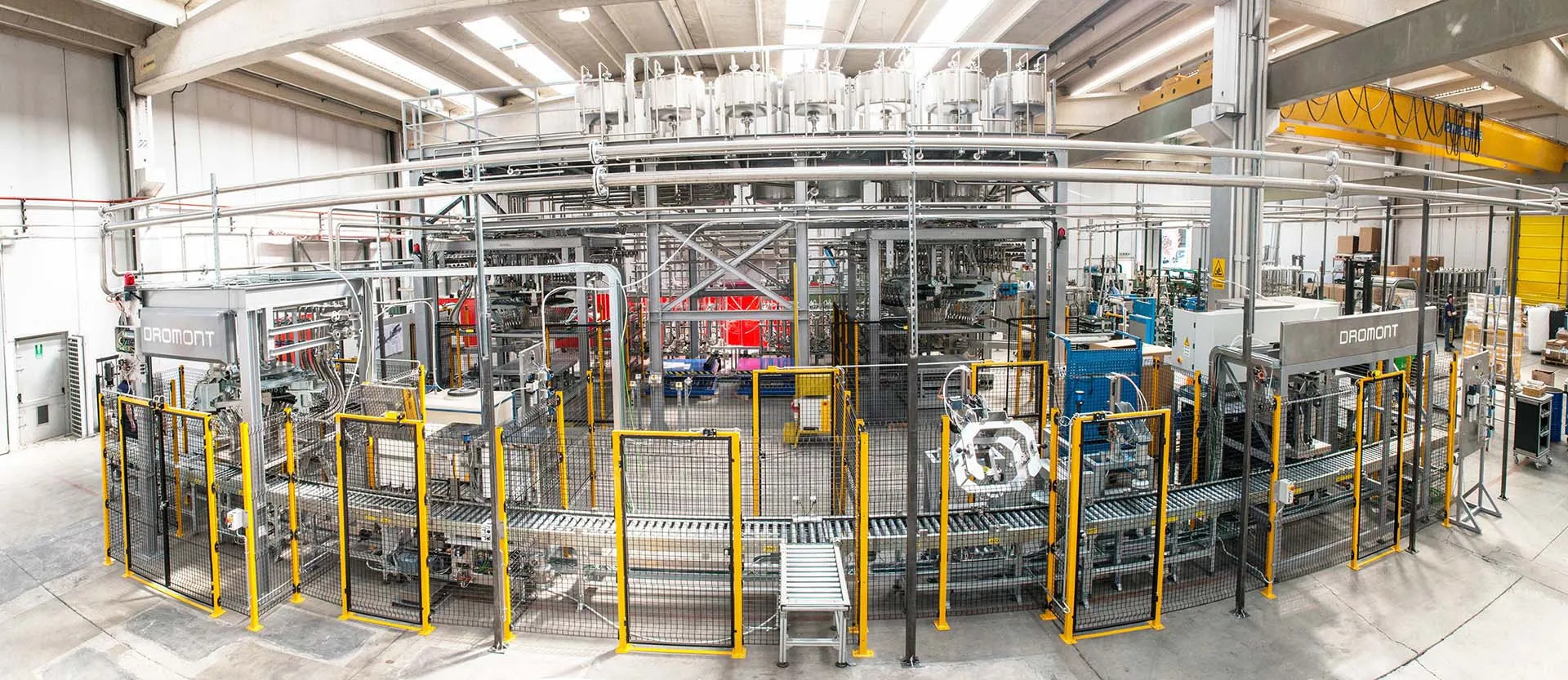

Selecta represents Dromont’s highest level of technology and it has been installed in over 500 large factories world-wide where continuous working cycle, reliability and accuracy are key factors.

Its special patented design allows for central dispensing of all components, guaranteeing the unique flexibility for dosing into small cans up to drums and large movable containers.

Available in three models, up to 100, up to 64 and up to 48 valves, Selecta is normally the high end system for manufacturing processes in both safe and hazardous area installations.

Its high accuracy reaches 0.05 g for small cans and a max flow rate of 9,000 lt/h. With seven step proportional dispensing management controlled by weight, set individually for each component, dispensing becomes a safe and traceable process.

The special O-ring free valves with patented design allow for long lasting reliability and the lifting device brings the container close to the dosing valve, thus avoiding splashing and reducing solvent fumes. The range of dosage containers is very wide: from 1 to 3000 kg and the system gives high flexibility for their handling.

Selecta offers a complete handling solution including conveyor lines from denesting of empty cans to labeling, dispensing, lidding, mixxing and palletizing.

Highly beneficial when custom colors are required, Selecta has been linked to the Micro lab dispensing system. This allows for very efficient color matching, automatic sampling and scale-up to production of the approved colors.

Up to 100 valves

Features

- Three Models up to 48, 64 and 100 valves

- Valve Sizes are 1″ and 2″

- Accuracy: +/- 0.05 g (depending on product viscosity and scale type)

- Flow rate of 3000 litres/h. with 1″ valves

- Flow rate of 9000 litres/h. with 2″ valves

- Range of Dosage Containers from 1 kg. to 3000 kg

Junior

Junior is the ideal dispensing system for medium levels of productivity and high accuracy requirement for the manufacturing industry.

A reliable machine, for safe and for hazardous area installations, Junior has been largely installed where production requires pails and drums.

Thanks to its exclusive patent with double circumferences of up to 32 valves, Junior allows for guaranteed dispensing quality with an accuracy of up to 0.1 g and a max flow rate of 500 lt/h. With seven step proportional dispensing management controlled by weight, set individually for each component, dispensing becomes a safe and traceable process.

The special O-ring free valves with patented design allow for long lasting reliability and the lifting device brings the container close to the dosing valve, thus avoiding splashing and reducing solvent fumes.

Junior offers a complete handling solution including conveyor lines from denesting of empty cans, to labeling, dispensing, lidding, mixing and palletizing.

Highly beneficial when custom colors are required, Junior has been linked to the Micro lab dispensing system.

This allows for very efficient color matching, automatic sampling and scale-up to the production of the approved colors.

Up to 32 valves

Features

- Expandability up to 32 valves

- Accuracy: +/- 0.1 g (depending on product viscosity)

- Flow rate 1000 litres/h (depending on product viscosity)

- Range of Dosage Containers from 20 kg. to 200 kg

Genius

Genius is Dromont’s compact smart dispensing system for medium-small level production requiring good accuracy.

A reliable machine, for safe and for hazardous area installations, Genius has been largely installed where production requires 20 liter pails only.

Up to 20 valves, Genius allows for guaranteed dispensing quality with an accuracy of up to 1 g and a max flow rate of 500 lt/h. With three steps proportional dispensing management, set individually for each component, dispensing becomes a safe traceable process controlled by weighing technology.

The special O-ring free valves with patented design allow for long lasting reliability and the lifting device brings the container close to the dosing valve, thus avoiding splashing and reducing solvent fumes.

Genius offers a complete handling solution including conveyor lines from denesting of empty cans, to labeling, dispensing, lidding, mixing and palletizing.

Up to 20 valves

Features

- Expandability up to 20 valves

- Accuracy: +/- 1 g (depending on product viscosity)

- Flow rate 500 litres/h (depending on product viscosity)

- Range of Dosage Containers from 20 kg. to 200 kg.

Selecta Offset / UV

Its special patented design allows for central dispensing of all components, guaranteeing the unique flexibility for dosing into small cans up to drums and large movable containers. Available in two models, up to 48 and up to 64 valves, Selecta Offset is normally the high end system for manufacturing processes for paste and high viscous products up to 1 million cPs or mPas.

Its high accuracy reaches 0.1 gram for small cans and a variable flow rate depending on product viscosity and pump sizing. With seven step proportional dispensing management controlled by weight, set individually for each component, dispensing becomes a safe and traceable process.

The special O-ring free valves with patented design allow for long lasting reliability, including special technology for high pressure resistance of 400 bar test pressure.

The range of dosage containers is very wide: from 1 to 3000 kg and the system gives high flexibility for their handling.

Selecta Offset offers a complete handling solution including conveyor lines for empty pots/pails to barcode labeling, dispensing and finished container buffer parking.

The Selecta UV is specifically dedicated to dispensing UV printing inks by optimizing stock levels and avoiding ink waste. The special Dromont UV valves ensure smooth dispensing operation by reducing friction and controlling the temperature in the inks.

Up to 64 valves

Features

- Two models with 48 or 64 valves

- Dispensing viscosity up to 1 million cPs or mPa

- Valve Sizes are 1″ and 2″

- Valve pressure test up to 400 bar

- Accuracy: +/- 0.1 g (depending on product viscosity and scale type)

- Flow rate of 1000 litres/h. with 1″ valves (depending on product viscosity and scale type)

- Flow rate of 3000 litres/h. with 2″ valves (depending on product viscosity and scale type)

- Range of Dosage Containers from 1 kg. to 3000 kg.

Junior Offset / UV

Junior Offset is the ideal dispensing system for medium levels of productivity and high accuracy requirement for the manufacturing industry.

A reliable machine, Junior Offset has been largely installed where production requires dispensing into max 50 liters containers.

Thanks to its exclusive patent with double circumferences of up to 20 valves, Junior Offset allows for guaranteed dispensing quality with an accuracy of up to 0.1 gram and a variable flow rate depending on product viscosity. With seven step proportional dispensing management controlled by weight, set individually for each component, dispensing becomes a safe and traceable process.

The special O-ring free valves with patented design allow for long lasting reliability, including special technology for high pressure resistance of 400 bar test pressure.

Junior Offset offers a complete handling solution including conveyor lines for empty pots/pails to barcode labeling, dispensing and finished container buffer parking.

The Junior UV is specifically dedicated to dispensing UV printing inks by optimizing stock levels and avoiding ink waste. The special Dromont UV valves ensure smooth dispensing operation by reducing friction and controlling the temperature in the inks.

Up to 32 valves

Features

- One model has up to 32 valves

- Dispensing viscosity up to 1 million cPs or mPa

- Valve pressure test up to 400 bar

- Accuracy: +/- 0.1 g (depending on product viscosity and scale type)

- Flow rate of 1000 litres/h. with 1″ valves (depending on product viscosity and scale type)

- Range of Dosage Containers from 1 kg. to 50 kg.

This department is capable of customizing the interface software to the customer’s exact needs, testing the software prior to installation, and programming the software to communicate with the customer’s systems. By using the very stable base platform of the Dromont software, Dromont’s engineers are able to then create many different options that will allow the customer to manage the entire plant.

Plant Software & Automation provides the user with a brand-new experience, by merging HMI, SCADA and MES into a single solution. The innovative architecture allows an unbelievable server-centric organization, capable of coordinating and connecting several clients, even on the web and with mobile devices.