Paint clean up unit

The first of its kind in the market, the patented EnviroWash System provides an environmentally friendly way of washing out painting tools, such as brushes and rollers, and minimizes the negative impact of traditional paint waste disposal methods.

The new Envirowash System is an innovative, water-based treatment system that turns paint wash-out into clean water and inert solid waste, allowing for easier and safer disposal.

Main advantages

The Envirowash System is efficient and fast – separating paint solids from 160 liters of water in only 2 hours. The largest system can handle up to 800 liters of paint washings and the Envirowash System can process any type of acrylic paint.

The Envirowash System helps the industry adhere to environmental guidelines as well as avoid stormwater pollution issues. Increased community expectations of environmentally responsible clean up processes make the system a must-have for the professional painter

Two models available: ES 160 and ES800

The ES 160 is a portable unit with a capacity of 160 liters and a processing time of 2 hours. Suitable for 1-man operations, it has an inner skin for extra strength and rigidity, plus a purpose-built sink insert providing a convenient wash up area. It can be easily transported.

- Capacity: 160 lt

- Dimensions: 105x77x66 cm

- Weight: 29Kg

The ES 800 is the largest Envirowash System and suits 5+ painter teams. The 800 liters system was designed for commercial construction sites and can cope with processing the higher quantities of paint washing associated with large building projects. A large ergonomic wash area provides excellent space for washing and storing paint equipment. A built-in pallet makes it easy for forklift movement and the unit is built to last. Wash hoses are supplied. Treatment time is 6 hours.

- Capacity: 800 lt

- Dimensions: 120x130x130 cm

- Weight: 72 Kg

Working principle

The units are easy to use and come with an easy-to-follow instructional DVD.

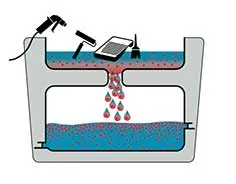

The units are made up of two parts – the sink and a separate filtration tank. They work by separating paint washings into clear water and solid paint.

The spray gun is used to wash rollers, brushes, paint trays, pots and anything else that has been used in the painting process.

Once the unit is full, treatment chemicals are used to separate the solid matter and water from the paint washings.

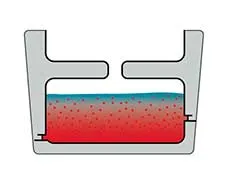

After 1-6 hours*, clear water remains on the top of the tank and paint sludge is left at the bottom.

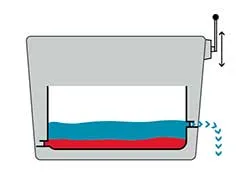

Clear water can be recycled for other trade related applications.

The remaining paint sludge is filtered and ready for removal and drying.

Once the residue is dry, it is ready to be disposed of as non-hazardous solid waste.

Typically, 450 liters of paint water discharge produces 5kg of solid paint residue.

*Treatment times vary depending on the capacity size of the unit and concentration of paint washings.

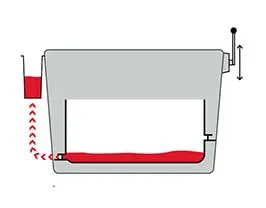

1. Wash painting equipment with spray gun

2. Filtration tank is full of paint washings

3. Separate water and solid matter

4. Clean water is released for reuse

5. Sludge is pumped out of the tank and filtered